|

||||||

- Dry drilling in concrete or reinforced concrete.

- The carbide center pin ensures accurate hole starting without bit walk.

- Peripheral threading on cutter for efficient removal of dust.

- All kinds of piping work for water, gas, electricity, air-conditioning and drainage jobs.

- Dry drilling in pre-cast concrete, concrete, reinforced concrete, and extrusion cement

(reinforcing bars below 12mm (1/2") dia.) - Drilling in Hume pipes, ceramic pipes, and PVC pipes.

| Cutter size: | o25mm to 310mm (o1" to 12-1/4") | ||

| Max. drilling depth: | Standard size: 150mm (5-7/8") (Cutter length: 180mm (7")) Long size: 220mm (8-11/16") (Cutter length: 250mm (9-7/8")) |

||

| Shank size: | Click here for the size table of the Poly-Clic shanks. | ||

| Applicable electric drill: Portable electric drills (in the rotary-only mode) | |||

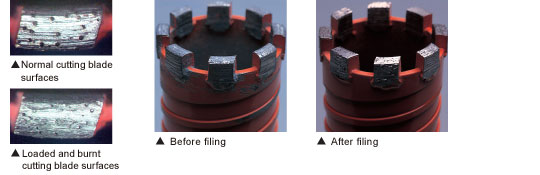

- During drilling, if any failures are caused on the cutting teeth in such a way that the teeth become imbalance, that its sharpness is lost suddenly, or that its color changes due to some reasons, drill several holes into an optional Diamond dressing plates, or a block or GC stone with the normal drilling method (dry type is applicable) for dressing.

- Drilling in block may accelerate the wear of cutting teeth.

Use the "Drimond core bits for block" or "Hyperdia core bits" for such a use. - Note that the wear of cutting teeth may become faster if you cut concrete soon after it is cured.

- If you use the tool in the percussion mode, chipped or broken tips may result. Always use it in the rotary-only mode.

- Always use this product for dry drilling. Wet drilling shortens the product life.

- Click here for the optimum rotation rate of electric drills and recommended electric drills.

| Copyright © 2005-2018 MIYANAGA Co., Ltd. All rights reserved. For customers in US and Canada, please visit www.miyanagaamerica.com. |